FoodClean Explains

Why Switch to Medium Pressure?

We’re approached by many food and drink manufacturing businesses that are finding it difficult to clean their production areas both quickly and thoroughly.

We’re approached by many food and drink manufacturing businesses that are finding it difficult to clean their production areas both quickly and thoroughly.

Whilst the right kind of disinfectants and detergents are key (take a look at our Chemistry range), the equipment you use is also of paramount importance.

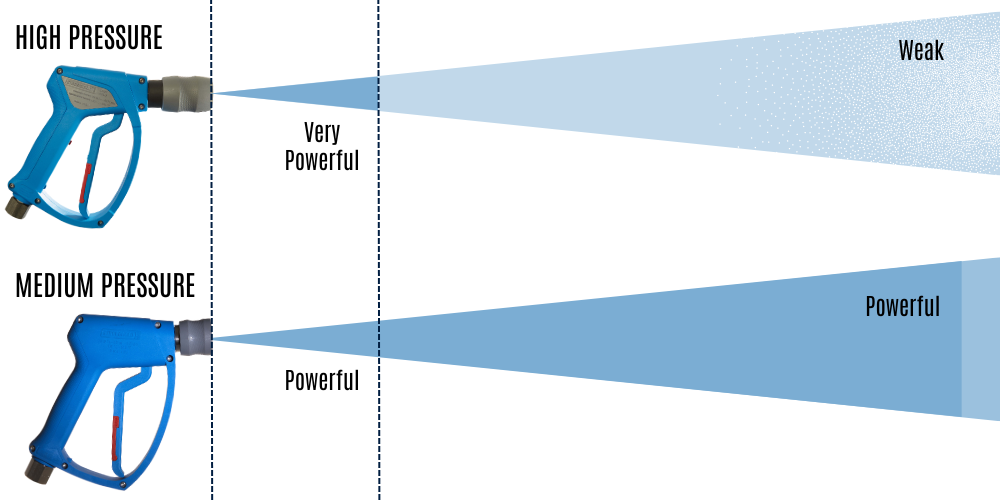

What’s more, the pressure being applied makes a big difference, as high-pressure systems aren’t always the optimum solution.

Why choose MP over HP?

The problem with high-pressure cleaning is that it often sprays the dirt, grime and contaminants elsewhere. It could be a case of the soil being moved to an area that is yet to be cleaned or, even worse, an area that had been disinfected only moments ago. This wastes time, labour hours, energy, water and chemicals whilst cutting into your company’s productivity and sustainability efforts. Medium pressure could very well be the solution, as it comes with multiple benefits.

Eliminate the “double cleaning effect”

When it comes to cleaning a factory, it really is a case of less is more.

By using medium-pressure equipment, the impact of the water strikesthe perfect balance between being powerful without veering into overspray issues. As a result, the area is cleaned in less time without uprooted dirt being blasted into other sections of the production zone.

Medium pressure means less… well… pressure

It isn’t just the factory floor and work areas that are under pressure when you’re using washdown equipment, it’s also the pump. Using high pressure means that the pump is under a lot of strain at all times, which can bring with it malfunctions, lower reliability and regular repair bills. With medium pressure, it’s the opposite without compromising on hygiene results, making it a win-win situation.

Run a cleaner, greener business

Many food manufacturing facilities are switching to medium-pressure hygiene systems because they’re also better for the environment. It makes sense that when a cleaning job is carried out efficiently, it requires less energy. In fact, a medium-pressure system uses just one-fifth the amount of energy as a high-pressure alternative, making it 80% more eco-friendly.

See our MP systems in action

We believe that food manufacturing companies should get to see how a system works before investing in it. That’s why we offer free onsite assessments and trials, which involves a FoodClean hygiene expert visiting your premises to assess what equipment you require and training your staff in how to use it to full effect. Alternatively, you can book a tour of the FoodClean Experience Centre in Lincoln, where you can enjoy a showcase of our wide range of cleaning solutions in a real-life factory environment.

Medium Pressure Videos

Book a free demo

If you’re interested in finding out how our medium-pressure systems will help you to achieve better results whilst cutting down your costs and carbon footprint, get in touch with one of our food hygiene specialists today on +44 (0) 1522 703703 or use our contact form.